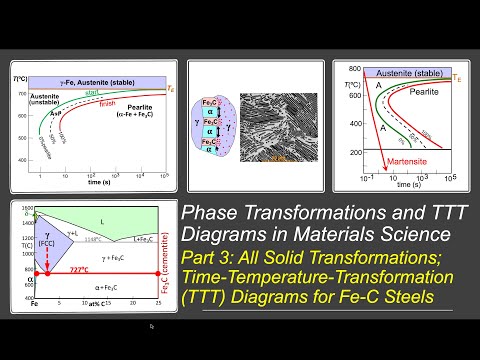

Martensite is the hardest form of steel, stabilized when the rapid quenching of Fe-C steel traps interstitial carbon atoms in the high-temperature face-centered cubic (FCC) phase of iron. This trapping of carbon causes the FCC phase to distort into a tetragonal structure through a “diffusionless” shearing mechanism, known as the martensitic transformation. During this process, the material undergoes multiple twinning to minimize stresses within the microstructure. In this video, designed for beginning materials science undergraduates, we’ll break down the mechanism behind martensite formation and explore how the twinned microstructure can be manipulated to create unique families of shape-memory metals. These fascinating materials have the ability to "remember" and return to their original shape after being deformed. With applications ranging from biomedical stents to the seemingly magical spoons in magic shows, shape-memory alloys have proven to be both practical and mesmerizing.

- 1269Просмотров

- 3 года назадОпубликованоPeter Davies

Fe-C Steels: (Part 2: The Formation of Martensite, Shape Memory Alloys)

Похожее видео

Популярное

reupload my edited video bb into song version

Chudo Zveryata

Потеряний снайпер 2часть

Потеряний снайпер 2 серія

лелик и барбарики заставка

Потерянный снайпер 7 серия

красный тигр

энчантималс реклама

пупок женщины

Красна я гадюка 5

Лихач 3 сезон 1-4

Красная годюка 5 часть

CPXV02 14

poland warsaw metro ride from swietokrzyska

потерений снайпер

Boo boo song the milk maks

Красная гадюка 17-20 серии

Городской снайпер 3

Умизуми

Красная гадюка 10 серия

Classic caliou misbehaves on a road

سكس

Universal real g major 13

Лихие 2

cum

Chudo Zveryata

Потеряний снайпер 2часть

Потеряний снайпер 2 серія

лелик и барбарики заставка

Потерянный снайпер 7 серия

красный тигр

энчантималс реклама

пупок женщины

Красна я гадюка 5

Лихач 3 сезон 1-4

Красная годюка 5 часть

CPXV02 14

poland warsaw metro ride from swietokrzyska

потерений снайпер

Boo boo song the milk maks

Красная гадюка 17-20 серии

Городской снайпер 3

Умизуми

Красная гадюка 10 серия

Classic caliou misbehaves on a road

سكس

Universal real g major 13

Лихие 2

cum

Новини