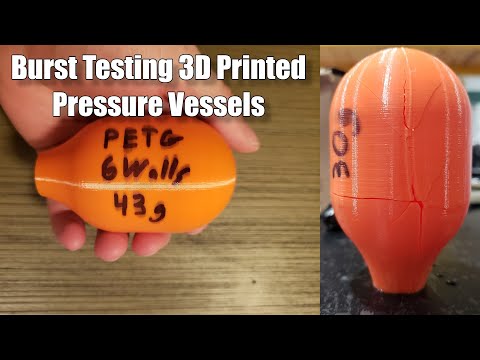

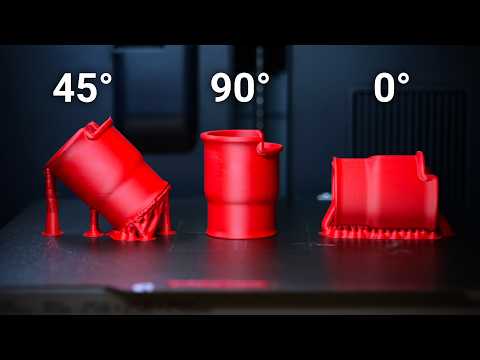

I've successfully 3D-printed watertight objects before, but this time, I wanted to push the limits—can a 3D-printed container be truly airtight? I designed, printed, and tested a container with a Schrader valve (like in a tire) and a screw-on lid with an O-ring seal. Sounds simple, right? Well, things didn’t go exactly as planned... In this video, I take you through my design process in FreeCAD, explain why my first version failed, and show how I improved the design. But the real fun begins with pressure testing! Using a bike pump, I pumped air into the container to see how much pressure it could handle. Some held over 12 bars (175 PSI!), while others... well, exploded spectacularly! 🚀💥 🔹 Can a 3D-printed container hold air? 🔹 Where does it leak, and why? 🔹 What happens when it reaches its limit? 🔹 What material works best — PLA, PETG, or ASA? I even set up high-speed footage (240 FPS) to capture the "Pressure-Activated Instant Deconstruction", but was it fast enough? Watch to find out! 👉 If you enjoy this type of 3D printing experiment, don’t forget to like, subscribe, and leave a comment! Let me know if you’ve ever tried making an airtight 3D print. 💡 Want to support my work? Buy me a coffee here: ☕ 🖨️ Check out my 3D printable designs: @Smoluch #3DPrinting #Airtight3DPrint #PressureTest #3DPrintedExplosion #DIY

- 3431Просмотров

- 9 месяцев назадОпубликованоTaboretum

3D-Printed Airtight Container – Will It Hold Pressure or Explode?

Похожее видео

Популярное

Go to your room

nude sexy

эвер афтер хай реклама

Preview 2 stars in the skynded^4

Deep house electro

Потеряный снайпер 9 серия

american pie college

машенька

titounis bus

Caliou misbehaves on car trip

мальчики

Жена чиновника 3 часть

Потеряный снайпер

УМ. БЕЛЫЙ ДЕЛЬФИН

Безжалостный гений часть5

Красная гадюка 16 серия

дисней добрлас

Boo boo song Dana

потерянный снайпер 8 серия

По дороге с облаками

Китай сериали

Патеринний снайпер.4серия

шатун сериал

nude sexy

эвер афтер хай реклама

Preview 2 stars in the skynded^4

Deep house electro

Потеряный снайпер 9 серия

american pie college

машенька

titounis bus

Caliou misbehaves on car trip

мальчики

Жена чиновника 3 часть

Потеряный снайпер

УМ. БЕЛЫЙ ДЕЛЬФИН

Безжалостный гений часть5

Красная гадюка 16 серия

дисней добрлас

Boo boo song Dana

потерянный снайпер 8 серия

По дороге с облаками

Китай сериали

Патеринний снайпер.4серия

шатун сериал

Новини