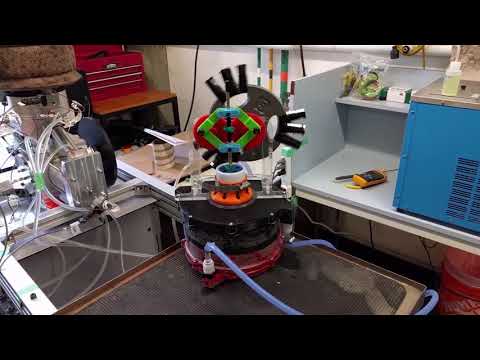

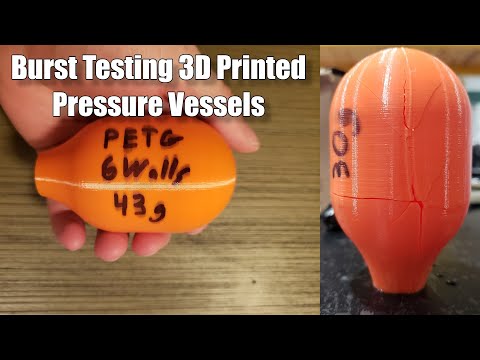

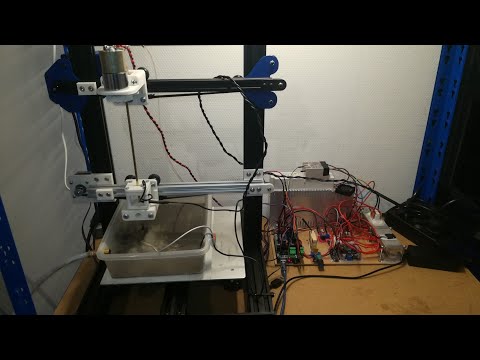

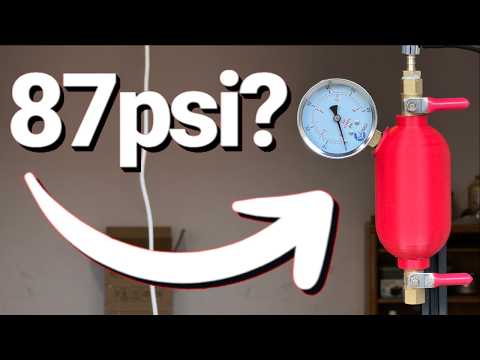

In this video I show how I 3D print gastight engine parts, treat them with Dichtol and make explosive pressure tests. If you want to support me and become a channel member you get access to exclusive content in the members area: A membership costs only 99 cents. Look out for Dichtol at: Thanks to Baptiste (alias OfficialyMax) we now have a Discord server: It would be very nice if we could discuss there everything about Stirling engines, 3D printing and more, thank you very much Baptiste. I did extensive compression tests to compare the strength of different materials, wall thicknesses, and printing technologies. To improve the performance of my thermoacoustic Stirling engine, I need high-pressure-resistant gastight or airtight components and would like to test the limits of 3D printed parts. I have already used a lot of 3D-printed parts in my engines. When airtightness was required, I printed with slightly overextrusion and treated the parts with epoxy resin. This method is somewhat effective but impractical and messy. Now I have looked at how the professionals do it and asked the company Diamant who sent me a few bottles of Dichtol to try out free of charge. I am giving my honest opinion here. I was simply provided with the product free of charge and have no specifications about the content. In addition to the components for the thermoacoustic Stirling engine, I also designed and printed a lot of test samples. I used PLA, PETG and ASA materials and printed with wall thicknesses of 2 or 3 mm and 1 to 4 wall loops. I also experimented with different printing techniques, especially with regard to the Z seam. Dichtol AM contains solvents. If you don't like the smell, it is better to use the water-based Dichtol AM Hydro instead. With test samples made of PETG with a wall thickness of 2 mm and only one wall loop, the layers tear open at 3 bar pressure. The ASA parts with thin wall thicknesses and a single wall layer exploded spectacularly at 4 bar. With 3mm wall thickness and 3 wall loops, ASA bursts at 8 bar. PETG with thick, solid walls is stable up to 11.5 bar; above this, it develops a small, permanent leak. I am very satisfied with these first results. With a solid printed wall thickness of 3 mm, pressures of up to 10 bar are possible, making the use of 3D-printed parts in the thermoacoustic Stirling engine perfectly reasonable. PETG has continued to prove itself as my favourite filament. Not only has it withstood the highest pressures without ever exploding, it has also always leaked in a controlled manner. The Dichtol fulfilled my expectations, although the test pieces were not optimal for the treatment, the strength of the printed layers determined the compressive strength and not the sealant. The printing settings of the seams and similar in the slicer are no longer so important, minor printing errors are reliably sealed by the Dichtol. I will now try out better test bodies and experiment with fibre-reinforced engineering filaments to see if they really offer better strength under compressive load. I will report on this in the next video. As always, I am very happy for your suggestions, criticism and comments. Many thanks for watching! Thanks for the background music: Song: Jim Yosef - Eclipse [NCS Release] Music provided by NoCopyrightSounds Free Download/Stream: Watch: • Jim Yosef - Eclipse | House | NCS

- 2275Просмотров

- 6 месяцев назадОпубликованоMy engines

3D print pressure tests for making gastight engine parts

Похожее видео

Популярное

the jerry springer show

Thiruttu payale amala paul

Кормление грудью

Preview Bing

Дельфин 4

Лихач 3 сезон 10-12

настольная игра реклама

Дорогу Нодди

ДЕННИ И ДЕДДИ

ЕДУНОВ ВИДИО

Потерянный снайпер два

опасность

Красная гадюка 17-20 серии

Tel ali

ЛЕТНИЕ КАНИКУЛЫ С СИДОМ

Потерянный снайпер 7

Тваринки-Бляшанки

Pedernal

Halloween boo boo s

Not scary universal g major 4

губка боб хорошие соседи

Lying ear picking

Сэмми и друзья

terminal

плюсплюс

Thiruttu payale amala paul

Кормление грудью

Preview Bing

Дельфин 4

Лихач 3 сезон 10-12

настольная игра реклама

Дорогу Нодди

ДЕННИ И ДЕДДИ

ЕДУНОВ ВИДИО

Потерянный снайпер два

опасность

Красная гадюка 17-20 серии

Tel ali

ЛЕТНИЕ КАНИКУЛЫ С СИДОМ

Потерянный снайпер 7

Тваринки-Бляшанки

Pedernal

Halloween boo boo s

Not scary universal g major 4

губка боб хорошие соседи

Lying ear picking

Сэмми и друзья

terminal

плюсплюс

Новини