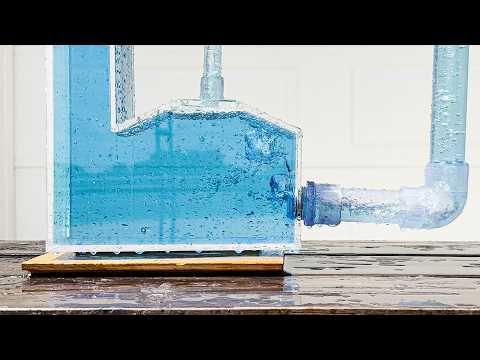

Bambu Lab US: Bambu Lab EU: This is a cycloidal drive, one of the most torque-dense gearboxes in existence. The one you see in the video is a simplified, very humble and small fully 3d printed cycloidal drive, but even in this form this extremely compact little unit has an 8:1 gear ratio. The orange eccentric shaft is our input and the blue load plate is our output. As you can see 8 rotations of the input give us 1 rotation of the output. An 8:1 gear ratio. Even a planetary gearset struggles to achieve such a gear ratio in so little space. 8:1 is actually pretty conservative by cycloidal drive stamdards with gear ratios of anywhere between 30:1 to 100:1 or even higher in some cases being common in cycloidal drives. But before I show you what a cycloidal drive can do and why it’s the go to gearbox for the most capable robots out there, I’d like to tell you about my progress in the world of 3d printing. I got into 3d printing 6 months ago with my Bambulab H2D, which has also printed all the stuff for today’s video. But cycloidal drives aren’t just about maximum torque increases in minimal packages. For something to be a torque god, it must be capable not just of increasing torque but also of surviving massive torque inputs, and this is another area where cycloidal drives make regular gears look like a joke. If you observe gears meshing, you will notice that all the torque is usually transferred through just one or two teeth. This is why gears must be wide if they want to handle significant torque. Wider gears of course result in a larger and heavier gearbox. But when they’re thick, conventional gears can be easily destroyed by shock loads, or a sudden application of high amounts of torque. A nice example of this are tuned engines with aggressive torque curves, you can have the same peak torque and horsepower in two engines, but the one with the more aggressively rising torque curve will blow a transmission whereas the other one will not. Electric motors are the definition of shock loads since they can output their peak torque pretty much instantly. The motors from your average EV would easily destroy the transmission of an equally powerful combustion vehicle. But they would definitely do nothing against a cycloidal drive. In fact many cycloidal drives are operated by some very brutal electrical motors and yet they complete thousands of trouble free service hour And that’s because there’s no teeth to break, no gears to strip. But it’s not just the toothless anatomy, it’s the fact that all the lobes of all the cycloids are in constant rolling contact with all the lobes or rollers of the housing. If we have 2 cycloids that’s 16 points of rolling contact. The pins and the ccycloidal gears again just rolling contact, there’s nothing to break. But cycloidal drives aren’t just more compact and stronger than conventional gearboxes, they’re also more accurate. Traditional gears need a relatively large amount of backlash to prevent them from binding and to ensure proper lubrication; it is this backlash that creates rotational play at the output and input shafts. And it usually gets worse the more gears you have in a transmission. But in a cycloidal drive we have constant rolling contact at a very large number of contact points, the result is that cycloidal drives typically have virtually zero backlash which means that robots equipped with them are capable of repeatably achieving incredible accuracy. Even a small 3d printed unit like this one with 0 bearings has surprisingly little backlash. Ok so it’s the be all and end all of gearboxes? The best gearbox? Of course not, because there’s no such thing, impressive achievements in one field are always paid for with a compromise in another. Yes, cycloidal drives are torque gods….but they are most certainly not speed gods. The one thing they suck at is high rpm operation. Why? Because of balance if you remember my ancient video on inline twin engines you may recall how none of these engines are actually perfectly balanced. If we observe the gears from the side we can see that there’s an offset between the gears and thus an offset between the forces, this creates a rocking couple which is trying to spin the gears about the center. At low rpm the forces of this rocking couple are absolutely negligible and irrelevant but at as speed increases they become more and more noticeably leading to vibrations and exponentially increased transmission noise and wear. And there you have it, the massive torque increase in minimal packages, together with shock load resistance and zero backlash make cycloidal absolutely perfect for robot arms and joints. A special thank you to my patrons: Daniel Peter Della Flora valqk Dave Westwood Zwoa Meda Beda Cole Philips Allan Mackay Sam Lutfi Alex #d4a #cycloidal

- 1324054Просмотров

- 2 недели назадОпубликованоdriving 4 answers

Toothless Gears Make Much More Torque Than Conventional Ones, Heres How. Cycloid Drive Explained

Похожее видео

Популярное

ЛЕТНИЕ КАНИКУЛЫ С СИДОМ

peeping on jewish girls

мальчики

Фильм потеряны снайпер

Valu temporada

Law and order criminal intent season 5 intro

Кормление грудью

ГАЗОН В ПУТИ ПОСЛЕДНИЕ

дорожная азбука

МИСТЕР МЭН

the jerry springer show

Крізь помилки минулого

Universal weird code

klaskyklaskyklaskyklasky joey 2 do go

humiliation

klaskyklaskyklaskyklasky gummy bear g major 26

Красная гадюка 17

Тротро

Потерянный снайпер 7 серия

forsaken teamers

die of death ost

ну погоди 18 выпуск

стражи провосудия 3

малыш вилли

peeping on jewish girls

мальчики

Фильм потеряны снайпер

Valu temporada

Law and order criminal intent season 5 intro

Кормление грудью

ГАЗОН В ПУТИ ПОСЛЕДНИЕ

дорожная азбука

МИСТЕР МЭН

the jerry springer show

Крізь помилки минулого

Universal weird code

klaskyklaskyklaskyklasky joey 2 do go

humiliation

klaskyklaskyklaskyklasky gummy bear g major 26

Красная гадюка 17

Тротро

Потерянный снайпер 7 серия

forsaken teamers

die of death ost

ну погоди 18 выпуск

стражи провосудия 3

малыш вилли

Новини