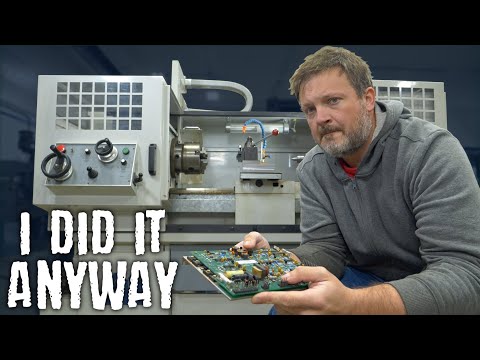

I was asked to make 3 large hex nuts out of 6061 alloy for a friends project and as this looked like something I could do by combining my CNC converted lathe and my Print NC Pro Router to make an interesting project I said why not, Drawn up in Fusion 360, as were the tool paths ......I hope you find it interesting please feel free to comment cheers Bill Also here is a link to one of John Saunders NYC CNC Videos on tricks and tips for selecting boundary's when doing your Cam I found this very helpful when doing the tool paths for this part. Thanks again for your interest Cheers Bill The time line 0:00 - 0:01 Start 0:02 - 0:30 Introduction to the project 0:31 - 0:40 Cutting the 6061 alloy blanks 0:41 - 0:48 Loading the G Code into the lathes Masso controller 0:49 - 1:43 Step roughing the face 0:44 - 2:40 Finish cut on face with spindle ramping to give constant surface speed 2:41 - 3:00 Finished running the program to machine the back of the nut 3:01 - 3:18 Loading the G Code into the Routers Masso controller 3:19 - 3:25 Probing the stock to set the WSC co ordinates 3:26 - 4:11 Milling the first step 5mm step down 4:12 - 5:21 Milling the second 5mm step down 5:22 - 5:41My Print NC Pro ball screws and Clear Path servos in action 5:42 - 6:00 Finishing the last part of the third 5mm step down using 2d adaptive 6:01 - 6:17 checking the progress on the Masso controller 6:18 - 6:25 Machining finished spindle returns to homing position 6:26 - 6:35 Last look at the Masso showing 38592 lines of code to complete the milling work 6:36 - 6:47 checking out the 3 finished nuts 6:48 - 7:26 The Final wrap up

- 480Просмотров

- 1 неделя назадОпубликованоWilliam Norris

Bills PrintNC Pro Router and CNC Lathe combining to making large custom 6061 Alloy Nuts

Похожее видео

Популярное

Переходный

щенячий патруль реклама

american pie college

игра снайпера 2 серия

Картоплини та дракони

Universal fanfare

Badalados assistimos 2022

Бобр добр

Preview Disney 2006 effects

Красная гадюка 15 серия

Nogizaka46 ohirisama tengoku

Коля оля и архимед

потеряій снайпер 5 серия

forsaken fandom

asmr tongue rubing

настя девочки

Городской снайпер 3

макс и катя

Nickelodeon

n-31-2000

Городской снайпер 2

Indian idol season 15 jai jai shiv shankar

Menu dvd Lex olivie remake monstros sa

красный тигр-1

щенячий патруль реклама

american pie college

игра снайпера 2 серия

Картоплини та дракони

Universal fanfare

Badalados assistimos 2022

Бобр добр

Preview Disney 2006 effects

Красная гадюка 15 серия

Nogizaka46 ohirisama tengoku

Коля оля и архимед

потеряій снайпер 5 серия

forsaken fandom

asmr tongue rubing

настя девочки

Городской снайпер 3

макс и катя

Nickelodeon

n-31-2000

Городской снайпер 2

Indian idol season 15 jai jai shiv shankar

Menu dvd Lex olivie remake monstros sa

красный тигр-1

Новини