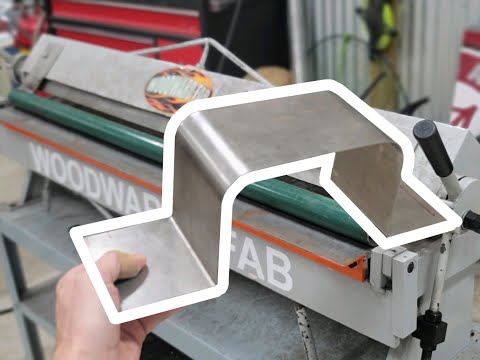

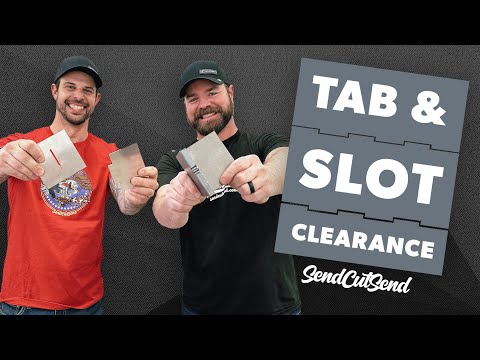

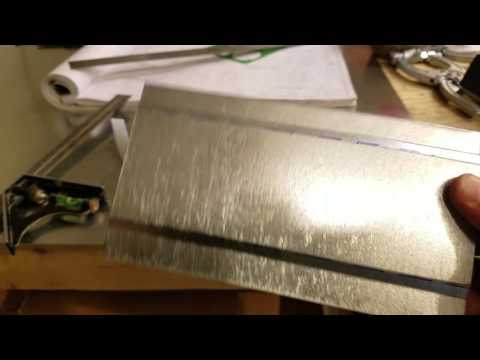

Welcome back to Cutting Corners with Jim and Jake! In today’s episode, we cover key DFM (Design for Manufacturing) principles to help you avoid common issues in sheet metal bending. ⏱️Timestamps⏱️ 00:52: Design For Manufacturing Team 01:34: Collisions in bending 02:47: Design with corner clearance in mind 04:45: Prevent tears and deformation with bend reliefs 07:15: The importance of correct flange lengths 08:12: Why you need corner reliefs 10:08: Why our machine can't bend short flanges Key Topics: Introduction to DFM for Bending: •Why DFM checks are crucial for bending success •Common issues that arise in bending, explained step-by-step Collision Challenges: •Collisions between parts and machines, and how to prevent them •Examples of part-to-part and part-to-machine collisions Corner Clearance Tips: •Why corner reliefs are essential for preventing tears and cracks •How to design with adequate clearance for successful bends Bend Relief and Distortion: •The role of bend relief cuts in avoiding warping and deformation •How hole placements near bends can impact part quality Flange Lengths and Short Flanges: •The importance of correct flange lengths to avoid bending failures •Examples of what happens with flanges that are too short Tips for Uneven and Parallel Flanges: •Solutions for dealing with uneven flanges and creating consistent bends •Importance of parallel edges for reliable alignment during bending If you’re working on sheet metal design or aiming to improve your technique, this episode provides essential tips to help you design better and avoid costly revisions. Have questions? Leave a comment, and let us know what you’d like covered in future videos. Like, subscribe, and upload your files for fast, accurate pricing on your parts! Custom sheet metal manufacturing and processing. From prototype to large production runs, get sale and assembly ready custom parts shipped in as little as 2 days; No minimum quantities; free US shipping on orders over $39; made In the USA: Follow us on Instagram:

- 12804Просмотров

- 1 год назадОпубликованоSendCutSend

Sheet Metal Bending: What to Avoid for Better Results - Cutting Corners Episode 9

Похожее видео

Популярное

лелик и барбарики заставка

союзмультфильм диск

незнайка за рулем

Preview 2 stars in the skynded^4

Красная гадюка 7 серия

Потерянный снайпер 4 серия

красный тарантул 3сезон

ЛЯПИК ЕДЕТ В ОКИДО

oggy

masculine men

Родрі

Universal g major 5 in leaf

Потерянный снайпер 8серия

Улица сезам

Noddy

Universal weird code

реклама для детей

Заставки Тижи TiJi

Лунтик

سكس

women relax at pool

Рики Смешарики

Безжалостный гений 3

agustin marin low voice i killed wi

союзмультфильм диск

незнайка за рулем

Preview 2 stars in the skynded^4

Красная гадюка 7 серия

Потерянный снайпер 4 серия

красный тарантул 3сезон

ЛЯПИК ЕДЕТ В ОКИДО

oggy

masculine men

Родрі

Universal g major 5 in leaf

Потерянный снайпер 8серия

Улица сезам

Noddy

Universal weird code

реклама для детей

Заставки Тижи TiJi

Лунтик

سكس

women relax at pool

Рики Смешарики

Безжалостный гений 3

agustin marin low voice i killed wi

Новини